Filter section

Water/steam heating section

Cooler section

Electrical heater section

|

|

› Long-life three-phase (3 x 230V, 3 x 400V) heating elements. |

Service section

Supply/exhaust air fan section

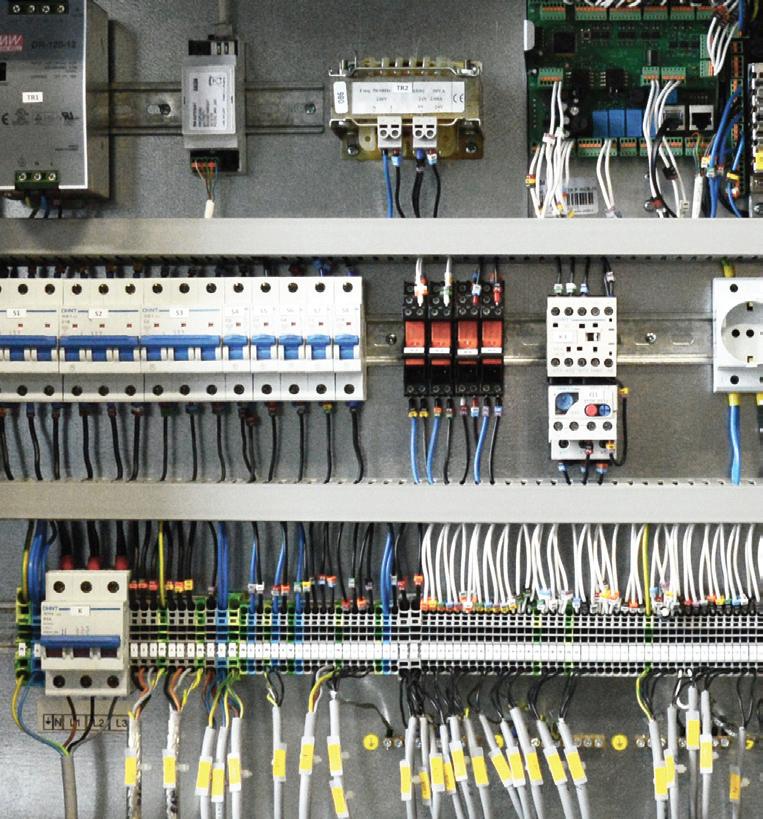

Control equipment section

Silencer section

Mixing section

|

|

› For mixing air flows. |

Rotor Heat-exchanger section

Cross-flow Plate Heat-exchanger section

Gas heater

Humidifier

Counter-flow plate heat exchanger section